The LRSDPA

The Low Resolution Double Prism Assembly (LRSDPA) is designed and manufactured at the 1st Insitute of Physics, in a collaboration with the Centre Spatial de Liege.

The close communication between Cologne scientists and mechanics from an early stage on has turned out to be crucial at all stages of development of the LRSDPA.

LRSDPA design overview

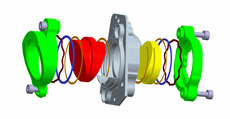

The purpose of the LRSDPA is to allow for an integration of two prisms, made of ZnS and Ge, accurately (70 microns accuracy) in the filterwheel of the MIRI imager.

The low resoulution spectroscopy mode of the MIRI imager then will allow to perform prism slit-spectroscopy in the wavelength-range from 5-10 microns at a resolution of 100. This mode is particularily aiming at spectroscopic analyses of very low surface brightness objects, such as deeply embedded (proto-)stars, or the first light-emitting galaxies that re-ionized the universe shortly after the big bang (see also SCIENCE page).

A general problem in satellites is the limitedness of available room. The other main challenge is that the prisms, intrinsic fragile crystals, will be exposed to extremely high levels of vibrations during the launch of the rocket.

The double prism assembly compensates for this and provides a safe mount of the prisms, with as few induced stress as possible. Springs provide a secure fixation - without overload - of the prisms, while gold-foils provide a soft contact between crystal and Aluminium parts.

The design, manufacturing and testing of the LRSDPA is based upon more than 3 years of research!

Qualification Tests

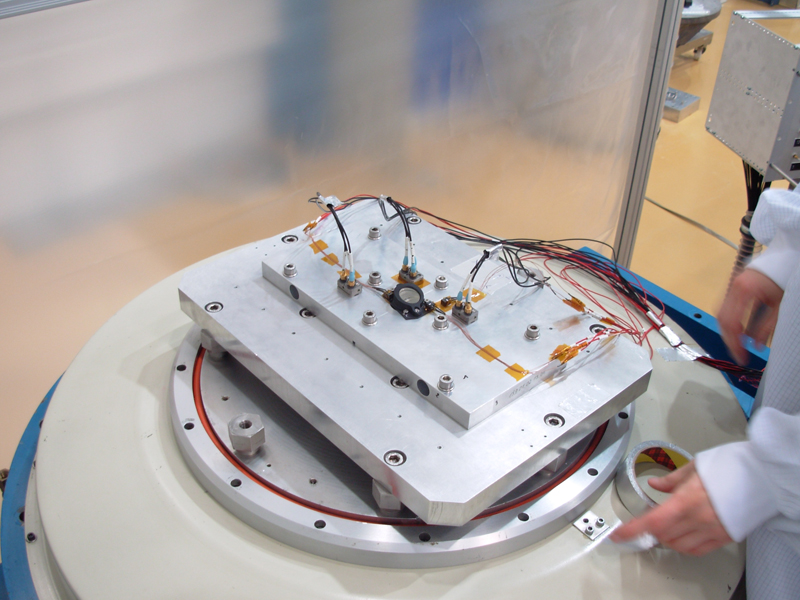

In march 2008, the LRSDPA qualification model ended its vibration test campaign at the Centre Spatial de Liege successfully. In this campaign, it was proven that the assembly can withstand 44 gRMS random vibrations, i.e. peak accelearations of 132 g, in axial directions (30g RMS in lateral directions)! The design is laid out for accelerations of 55g RMS, but even these 44g RMS were just below the capability-limit of CSL's shaker. For this test campaign, Damian Moratschke and Sebastian Fischer accompanied the LRSDPA during all stages of tests.

Flight model manufacturing

The final design of the LRSPDA has gone through various iterations of improvements and adjustments to filterwheel requirements. Only the unbureaucratic, direct in-house communication between workshop and scientist allowed a successful production of flight-hardware in a timely and otherwise extremely costly manner.

The machining of the LRSDPA structural parts exhausted the limits of feasability of our 5-axis computer guided CNC milling machine, but critical surfaces in the different parts have been machined with an accurateness of up to 3 microns.

A lot of effort has been put into the metrology of the parts machined at Cologne. Only these guarantee a correct alignment of the prisms in the filterwheel. The "Institut f;uumlr Bildsame Formgebung" (IBF) of the University of Aachen has performed a 3D-scanning of 6 sets of DPAs, out of which the best 3 were chosen for qualification, flight spare and flight model.

During the qualification test campaign, the springs in use turned out to be of bad quality and we produced CuBe 2 springs in house. Now, the two prisms, which are fabricated at AMOS, are the only two components of the LRSDPA which are not provided by University of Cologne.